產(chǎn)品中心

Product center

普瑞斯照明四大優(yōu)勢

1、21年專注燈具研發(fā)·創(chuàng)新

● 21年燈具生產(chǎn)經(jīng)驗(yàn),產(chǎn)品遠(yuǎn)銷國內(nèi)外

● 高標(biāo)準(zhǔn)設(shè)計(jì),適用于各各種嚴(yán)格場合

● 在車間,道路,辦公,防爆,防腐等場合均

有適合燈具

專業(yè)從事LED照明燈具的研發(fā)生產(chǎn)及銷售

2、只生產(chǎn)高品質(zhì)燈具

● 高光效·長壽命·足功率 關(guān)鍵元器件全

部進(jìn)口

● 核心技術(shù),研發(fā)力量雄厚

● 針對特定場所研發(fā)燈具,可為客戶定制

燈具

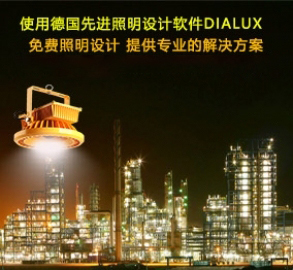

3、售前有服務(wù),售后有保障

● 技術(shù)力量雄厚,專業(yè)照明工程師為您

做照明設(shè)計(jì),節(jié)能分析

● LED燈具整燈質(zhì)保三年

● 一對一售后服務(wù)跟蹤,2小時(shí)快速響應(yīng),

即刻處理

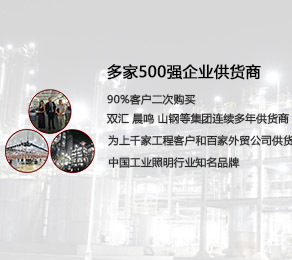

4、中國優(yōu)秀工程商的最佳選擇

● 質(zhì)量有保障,產(chǎn)品競爭力明顯

● 廠家直銷,價(jià)格一步到位

● 工程用燈具全部購齊,讓您更省心,

提升體驗(yàn)滿意度

工程案例

在照明領(lǐng)域有21年的豐富經(jīng)驗(yàn),3000+個(gè)工程項(xiàng)目經(jīng)驗(yàn),100000+家客戶選擇我們,90%客戶會二次購買

關(guān)于我們

About us

普瑞斯照明是專業(yè)從事LED照明燈具研發(fā)生產(chǎn)及銷售的高科技企業(yè),技術(shù)實(shí)力雄厚,與許多高等院校科研單位合作,擁有高科技核心技術(shù),為客戶提供專業(yè)解決方案,在照明領(lǐng)域有21年的豐富經(jīng)驗(yàn),研發(fā)生產(chǎn)的LED三防燈、LED工礦燈、LED防爆燈、LED投光燈、LED隧道燈、場館燈、養(yǎng)殖燈等廣泛應(yīng)用于食品、機(jī)械、冶金、汽車、電力、化工、紡織、造紙等行業(yè),多家500強(qiáng)企業(yè)采購我們的產(chǎn)品,如中國重汽、山東鋼鐵、中聯(lián)水泥、晨鳴集團(tuán)、雙匯集團(tuán),并且多次重復(fù)購買,成為常年供貨商。每年超過200家工程客戶,現(xiàn)有幾千家客戶在使用,銷售遍及全國各省市并出口歐美東南亞等國外市場。

普瑞斯照明科技有限公司

公司動態(tài)

News feed

2019-07-05

普瑞斯照明是專業(yè)從事LED照明燈具研發(fā)生產(chǎn)及銷售的高科技企業(yè),技術(shù)實(shí)力雄厚,與許多高等院校科研單位合作,擁有高科技核心技術(shù),為客戶提供專業(yè)解決方案。

LED三防燈 冷庫專用照明燈具系列的冷庫燈,是我公司針對冷庫保鮮系統(tǒng)設(shè)計(jì)的一款高效美觀的冷庫專用照明燈具LED三防燈照明產(chǎn)品。

常言道:“窮則變,變則通”。在LED照明燈飾行業(yè)淡季來襲之時(shí),積極求變,讓企業(yè)不但可以做到“淡季不談”,甚至可以做得比旺季更好...

近日,半導(dǎo)體照明技術(shù)評價(jià)聯(lián)盟成立大會在北京舉行,根據(jù)中國輕工業(yè)聯(lián)合會中輕聯(lián)標(biāo)準(zhǔn)[2013]192號文件批準(zhǔn),中國首個(gè)半導(dǎo)體照明技術(shù)...